Batteries can release high energies and the safety requirements for nickel- and lithium-based batteries and cells for portable applications are harmonized under IEC 62133. The standard came into effect in 2012 to reduce the global risk in transporting, storing and operating batteries.

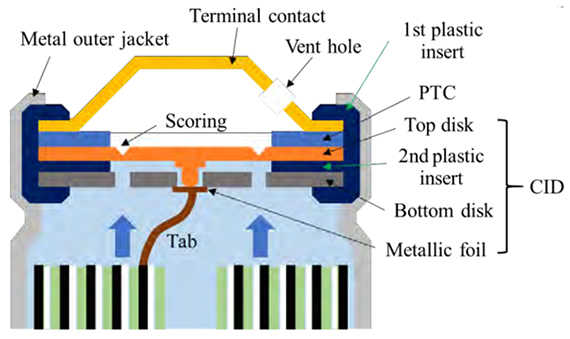

The most basic safety device in a battery is a fuse that opens on high current. Some fuses open permanently and render the battery useless; others are more forgiving and reset. Figure 1 illustrates the top of an 18650 cell for Li-ion with built-in safety features.

The resistance of the positive thermal coefficient (PTC) (blue) is low during normal operation and increases when the temperature rises above a critical level to reduce current flow. The PTC is reversible and returns to high conductivity when the temperature normalizes.

The current interrupt device (CID) is a fuse-type device that cuts off the electrical circuit permanently when triggered by excessive cell pressure, high temperature, or high voltage, depending on design. In Figure 1, the CID operates by pressure. When the internal pressure increases to about 1,000kPa, the scored top disk (orange) breaks, separates from the metallic foil (brown) and disconnects the current flow. This also allows gas to vent.

The last safety device is the vent that releases gas during an anomaly and can be resealed. However, the pressure of a disintegrating cell can be so large that the gases are unable to escape in an orderly way and venting with flame occurs. In some cases the top of the cell escapes like a bullet from a shotgun. Similar to a nuclear meltdown that cannot be stopped once in progress; a Li-ion battery once in disintegration should be allowed to burn out in a safe place with ventilation.

PTC (blue) increases resistance by heat to reduce electrical current. The effect is reversible. CID consists of a top disk (orange) that breaks under pressure and permanently disconnects the current flow.

Protection devices have a residual resistance that causes a slight decrease in overall performance due to a resistive voltage drop. Not all cells have built-in protections and the responsibility for safety in its absence falls to the Battery Management System (BMS).

Further layers of safeguards can include solid-state switches in a circuit that is attached to the battery pack to measure current and voltage and disconnect the circuit if the values are too high. Protection circuits for Li-ion packs are mandatory. (See BU-304b: Making Lithium-ion Safe)

More information on why batteries fail, what the user can do when a battery overheats and simple guidelines using Lithium-ion Batteries are described in BU-304a: Safety Concerns with Li-ion.

Intrinsically Safe Batteries

Safety is vitally important when using electronic devices in hazardous areas. Intrinsic safety (IS) ensures harmless operation in areas where an electric spark could ignite flammable gas or dust. Hazardous areas include oil refineries, chemical plants, grain elevators and textile mills.

All electronic devices entering a hazardous area must be intrinsically safe. This includes two-way radios, mobile phones, laptops, cameras, flashlights, gas detectors, test devices and medical instruments, even when powered with primary AA and AAA cells. Intrinsically safe devices and batteries contain protection circuits that prevent excessive currents that could lead to high heat, sparks and explosion. The hazard levels are subdivided into these four disciplines.

The main classifications for intrinsic safety are divisions and zones. Division is typically used in North America; zone originated in Europe but is now used worldwide. The two classifications have much in common, but there are differences in risk perception.

DIVISIONS (North America)

1. Types of Hazardous Materials and likelihood of presence

Class I Flammable gas/vapors or liquids in petroleum refineries, utility gas plants.

Class II Combustible dust in grain elevators, coal preparations plants.

Class III Ignitable fibers and flyings in textile mills, wood processing creating sawdust, etc.

Division I Hazardous materials likely to exist in ignitable concentrations under normal use.

Division II Hazardous materials unlikely to exist in ignitable concentrations under normal use.

ZONES (Europe and rest of the world)

Zone 0 Gas/vapors exist continuously or for long periods under normal use.

Zone 1 Gas/vapors likely to exist under normal use.

Zone 2 Gas/vapors unlikely to exist under normal use.

Zone 20 Dust exists continuously or for long periods under normal use.

Zone 21 Dust likely to exist under normal use

Zone 22 Dust unlikely to exist under normal use

2. Potency of Hazardous Material (Groups from A to G)

A hazardous material is given a designation of: Acetylene (A), hydrogen (B), ethylene (C), propane, gasoline, etc. (D), metal dust (E), coal dust (F) and grain dust (G).

3. Temperature Codes (from T1 to T6)

The explosion danger of gases or combustible dust is affected by surface temperature. T1 is a hot 450ºC (842ºF); T6 is a moderate 85ºC (185ºF). All other temperatures fall in between.

Intrinsic safety requirements vary from country to country. North America has the Factory Mutual Research Corporation, Underwriters Laboratories (UL) and Canadian Standards Association (CSA); Europe has the ATEX directive; while other countries follow the IECEx standards. Many countries recognize harmonized IEC 60079.

References

[1] Source: CALCE (Center for Advanced Life Cycle Engineering)

Comments

Looking for comments from the previous website?

Comments from the previous website are not compatible with our new commenting system but we have preserved them so our users can still reference and make use the information in them.